[ad_1]

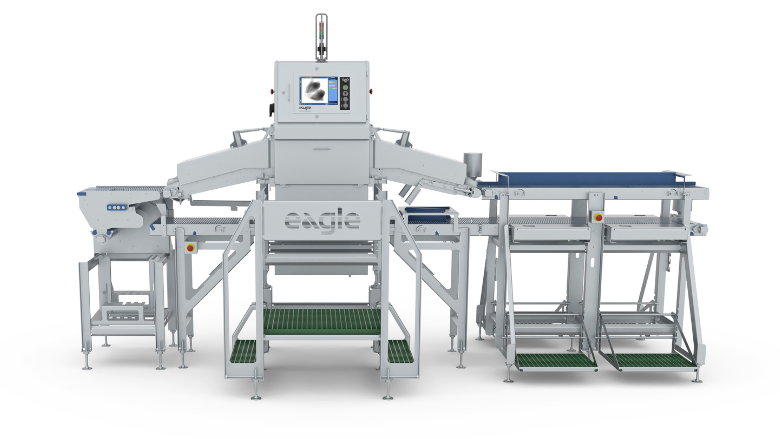

Eagle Product Inspection just lately launched its newest revolutionary answer for the poultry processing trade, MAXIMIZER RMI. Hygienically constructed with a dedication to enhancing bone detection and lowering labor associated to product rejects, this answer is designed to maximise product throughput and profitability whereas guaranteeing the best stage of security requirements are met.

Key to the MAXIMIZER is its integration with the Eagle™ RMI 400 X-ray machine. The machine is supplied with Eagle’s superior picture evaluation software program, SimulTask™ PRO, and enhanced twin power detector, PXT™. This mix gives unparalleled bone and metallic detection, lowering false rejects and minimizing operational challenges associated to handbook labor. The result’s a streamlined manufacturing course of that will increase general effectivity.

A standout function of the MAXIMIZER RMI is its twin lanes that run as much as 120 items per lane per minute. This function, together with the automated reject administration system, gives a fast and environment friendly inspection course of, considerably growing the speed of manufacturing. MAXIMIZER RMI has been purpose-built to effortlessly disassemble and assemble for fast and straightforward sanitation, one other main benefit for poultry environments the place fixed harsh cleansing is required.

Eagle Product Inspection continues to innovate within the space of meals inspection, with MAXIMIZER representing the newest in an extended line of pioneering options designed to reinforce the meals manufacturing trade’s capabilities. Stay demonstrations of the MAXIMIZER RMI shall be held at Eagle’s sales space (C-46137) on the upcoming Worldwide Manufacturing and Processing Expo (IPPE) happening January 3–February 1, 2024, in Atlanta, Georgia.

Eagle Product Inspection: www.eaglepi.com

[ad_2]

Source link